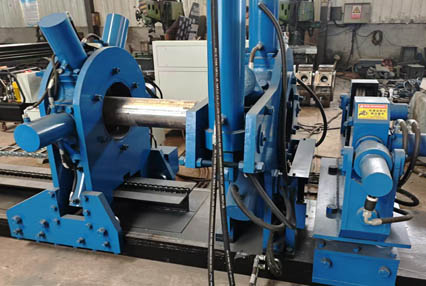

Hydraulic Assembly and Disassembly Frame

The Hydraulic Assembly and Disassembly is tailored to China’s current industrial conditions and requirements, ensuring proper make-up and break-out of API-standard casing, couplings, drill-pipe connections, drill pipe, heavyweight drill pipe, drill collars, and similar components. This specialized assembly/disassembly equipment is used for the removal, installation, and maintenance of various petroleum and geological screw-drilling tools, tubing strings, non-magnetic instruments, and other downhole tools.

Equipment Overview

The Hydraulic Assembly and Disassembly Frame combines cutting-edge domestic and international technologies, customized to fit China’s industrial landscape. It guarantees the accurate make-up and break-out of API-standard components. This specialized rig serves as the go-to solution for the removal, installation, and maintenance of a wide range of petroleum and geological downhole tools.

Equipment Components

The Hydraulic Assembly and Disassembly Frame consists of the following main units:

- Hydraulic Control Console

- Supplies the hydraulic power source, indicator gauges, and control levers.

- Hydraulic Clamps

- Comprises fixed and movable clamp assemblies to securely grip workpieces and apply torque.

- Hydraulic Make/Break Unit

- Applies the necessary make-up torque to tighten threaded connections and provides sufficient reverse torque (maximum rotation > 30° per cycle) to loosen them.

- Rapid Make/Break Mechanism

- Enables quick pre-tightening during make-up and fast release during break-out of threaded components.

- Hydraulic Auxiliary Support Assembly

- Features three movable, bidirectional supports mounted on the base at each end of the main frame, working with the main unit to stabilize workpieces during assembly/disassembly.

- Equipment Base

- Made up of a central main base and two extended auxiliary bases for enhanced stability.

- Tail-End Push-Pull Unit

- Performs the axial insertion or extraction of the workpiece.

Technical Parameters

| Parameter | Metric System | Imperial System |

| Motor power | 22KW | – |

| Diameter range of clamping workpiece | 60–130mm | 2 3/8”–12 1/8” |

| Maximum release torque | 185KN.m | 1320000ft-lbs |

| Maximum up-button torque | 155KN.m | 110000ft-lbs |

| Maximum torque for fast buckle | 5KN.m | – |

| Maximum thrust | 245KN | – |

| Maximum pulling force | 195KN | – |

| System working pressure | 16Mpa | – |

| Weight | 12.6t | – |

Note: The diameter size can be customized according to user requirements.